Return to flip book view

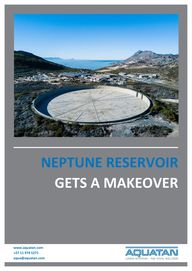

NEPTUNE RESERVOIR GETS A MAKEOVER www aquatan com 27 11 974 5271 aqua aquatan com

BACKGROUND Aquatan s commitment to protecting water resources and the environment has underpinned its cuttingedge innovations from the time of its founding in 1966 MD Piet Meyer argues that implementing geosynthetic solutions to conserve and optimise water use is one of the most economic efficient and reliable ways of sustaining water supplies even and perhaps especially in times of drought It is also important that we efficiently utilize existing storage facilities as we live in a water scarce country and that long term waterpreservation strategies should become the norm Furthermore it may be worthwhile to consider the Western Cape s current severe drought within the context of a number of exacerbating factors It is recorded that the City has experienced a 55 population increase since 1995 Rainfall patterns are also changing owing to global warming All of the above are a stark reminder that it is vital not only to construct new dams and reservoirs but more so to maintain the infrastructure already in place Page 2 of 5 A very good example is the recent rehabilitation of an important reservoir in the Cape Simon s Town has two reservoirs the Prince George Reservoir and the aptly named Neptune Reservoir Both circular reservoirs constructed in 1940 were originally uncovered As time went by residents started complaining about the taste of the water and it was discovered that strong winds were dumping pollen into the reservoirs It was therefore decided to install a roof in 1989 The cost of a concrete roof was prohibitive with the result that Aquatan suggested installing a Hypalon HDPE combined floating cover system The novel idea was accepted and the cover was installed in the Neptune Reservoir which has a capacity of 55 ML diameter of 112 6 meter and a wall height of 6 meter Aquatan had been earning praise for its innovative floating cover design since the installation of its first cover in 1984 The 1989 Neptune floating cover consisted for economic reasons of HDPE projected floor area and Hypalon vertical walls and included a series of buoyant floats and weights to maintain the cover under tension The life expectancy of the original floating cover roof was 10 years It however serviced the community for 28 years The time had however come to replace the cover and Aquatan was awarded the tender to do so in June 2016 ORIGINAL SCOPE The intended scope of the project was to remove and dispose of the old cover AQUATAN HAS BEEN EARNING PRAISE FOR ITS INNOVATIVE FLOATING COVER DESIGNS SINCE THE INSTALLATION OF ITS FIRST COVER IN 1984 including the stainless steel straps at the top of the wall and the existing abrasion layer Minor concrete repairs were intended as well as resealing of the expansion joints of the wall and floor A new cover would then be installed with a new abrasion layer on the wall and new steel strapping at the top of the wall Aquatan were also to fit new rainwater removal pumps which would connect newly laid

installing an engineered high density foam to bridge the joint width To mitigate the unexpected additional cost to the City of Cape Town and following a technical evaluation of the 28 year old stainless steel baton and bolts Aquatan proposed sandblasting and reusing the same baton strapping at the top of the wall discharge piping to a manhole WHAT AQUATAN FOUND As the reservoir had been covered for 28 years it was not possible to gauge the condition of the concrete before starting the work Once the cover was removed and recycled 3 600 m of expansion joints were discovered on the floor varying in widths from 75 mm to 100 mm which were sealed 77 years ago with a bituminous sealant The walls had 30 vertical expansion joints each measuring 300 mm wide also sealed with a bituminous sealant It became clear that it was impractical to seal these joints with conventional joint sealants due to the huge cost and the inconsistency of the actual joint widths Page 3 of 5 PROPOSED SOLUTION The City of Cape Town asked Aquatan to supply alternative costings to either line the entire reservoir with a 2 0 mm Driline Linear Low Density Polyethylene LLDPE or install a Polyolefin bandage over each joint The lining of the entire reservoir proved to be the more holistic cost effective and practical solution because it would also address remediable cracks difficult to detect in the concrete In the value engineering process Aquatan proposed installing 300 mm wide aluminium strips over all the floor expansion joints to avoid the Driline geomembrane being forced into the varying width joints by the near 5 6 m water head on the 2 0 mm Driline at full capacity of the reservoir The wall joints were addressed by MY SINCERE THANKS FOR AQUATAN S HUGE EFFORT TO MAKE SURE THAT CONTRACT 140Q 2015 16 WAS COMPLETED ON TIME WITHIN BUDGET AND TO HIGH QUALITY STANDARDS The site included various civil engineering disciplines such as earthworks as well as civil and mechanical pipe and valve works which together with the Driline geomembrane and Floating Cover required full time management by an experienced Site Agent Aquatan also proposed a leakage detection system

comprising a 4 0 mm high spacer layer Hi Drain 750 across the entire floor area of the reservoir under the 2 0 mm Driline geomembrane The leakage detection system is connected to atmosphere to monitor and mitigate potential leaks in the 2 0 mm Driline This was well received by the City of Cape Town because it would mitigate water losses In order to connect the gravity driven leakage detection system to atmosphere a pipe was installed by core drilling through the reservoir wall in to the scour sump the lowest point of the reservoir and directional drilling through the soil to daylight in a constructed headwall structure to which any leaks would flow and be monitored The drilling was required in terms of the City s commendable Protection of Flora and Fauna contract condition No vegetation were allowed to be removed damaged or disturbed This condition required Aquatan to relocate 13 snakes and one tortoise as well as barricading the breeding ground of a Spotted Thickknee until the chicks hatched and found their way Aquatan s Electric Leak Detection system a post Page 4 of 5 construction quality assurance method was applied on the Driline on both the floor and the vertical walls of the reservoir to detect and eliminate any discrepancies in the liner before the cover was installed GETTING IT DONE The Driline was delivered to site in 7 0 m wide rolls and lowered into the reservoir by a crane Using the floor of the reservoir and careful measurements the wall panels were premanufactured in predetermined carefully measured modules and the floor liner was pre cut to the required lengths after taking the curvature of the reservoir into consideration The same process was used for the Coolpro Reinforced Polypropylene RFPP floating cover roof material but pre cut and seamed at Aquatan s factory in Isando Johannesburg The wall modules both Driline and Coolpro were then installed into position using custom made tools which minimised the handling of the liners and the very complicated vertical seams on site The floor of the reservoir was then installed with both liners following one another like building a puzzle THE RESULT Aquatan completed the works on 26 May 2017 ten working days before the stipulated end date of 6 June 2017 It is noteworthy to mention that amongst all the other benefits associated with a Floating Cover the Coolpro cover and Driline liner withstood the reported wind speeds of up to 150 Km per hour which confronted the Western Cape and the reservoir just recently Anver Seconds City of Cape Town s Senior Professional Officer Planning Design

Projects has the following comments about Aquatan s work I would like to extend my appreciation towards all involved in the successful completion of Contract No 140Q 2015 16 Replacement of the floating roof on the Neptune Reservoir Simon s Town in time and within the approved budget allocation He added I appreciate the professionalism in which the project was completed and congratulate all for their dedication and efforts UWP Consulting were appointed by City of Cape Town as the consulting engineers for the project Ehrane Holderness Pr Eng PMP Associate at UWP Consulting Pty Ltd adds to the above My sincere thanks for Aquatan s huge effort to make sure that contract 140Q 2015 16 was completed on time within budget and to high quality standards She further commented I also believe that significant value was added through your recommendations to improve infrastructure impacting on the safety functionality and aesthetics of Neptune Reservoir The efficiency with which unexpected issues after the Practical Completion were Page 5 of 5 handled is also commendable The success in completing projects such as these can largely be ascribed to our 50 years experience in the lining business says Meyer Aquatan has always been known for its innovative installation methods and its professional site agents and installation crews As Aquatan is a certified and IAGI accredited Approved Installation Contractor AIC its crews predominantly consist of IAGI Certified Welding Technicians CWT However no amount of experience expertise or certification can make up for constant communication with the client and other stakeholders involved in the project